Heat Transfer Film

I.Transfer

I.TRANSFER

Heat Transfer Film

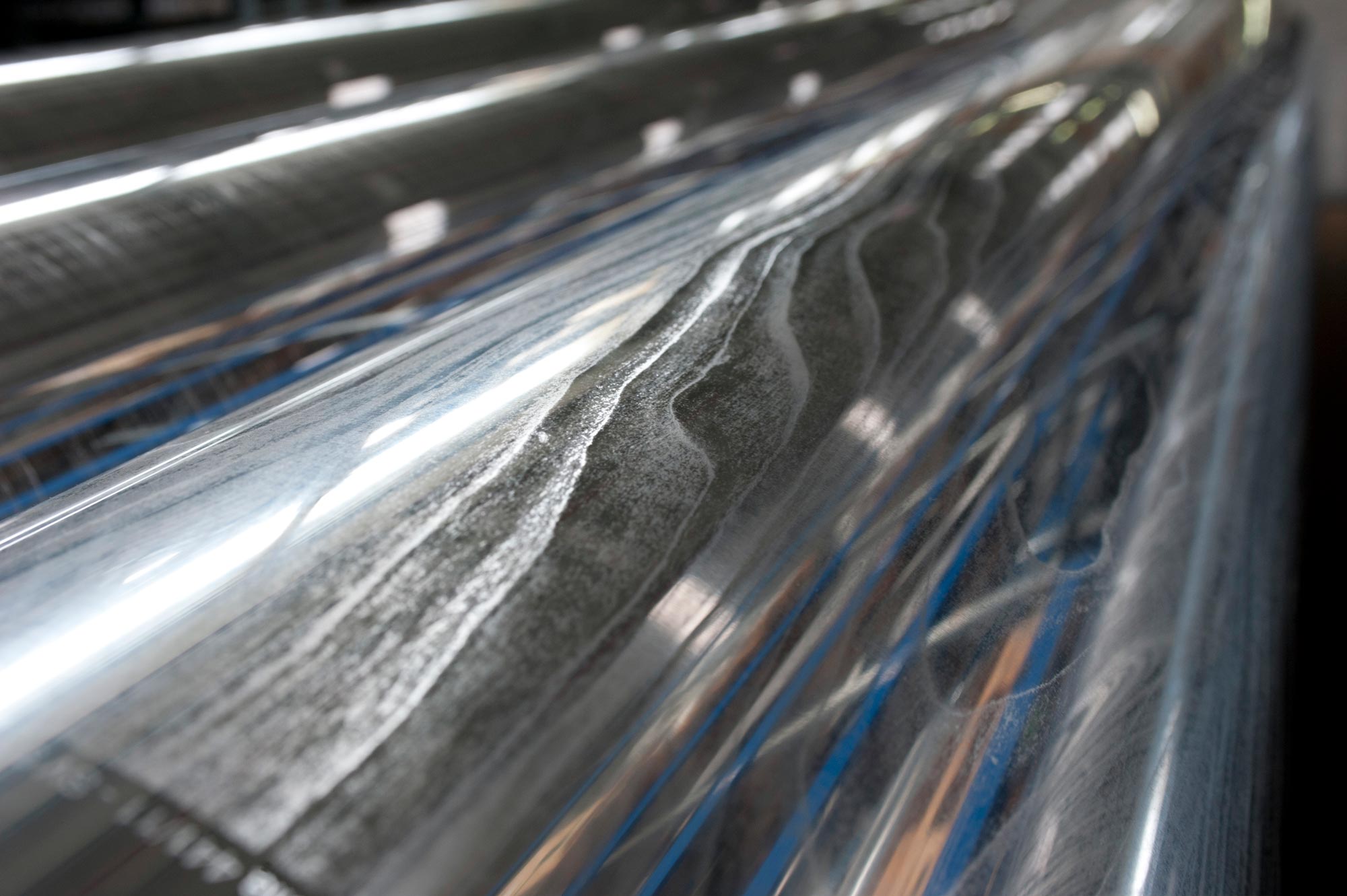

At I.DEK we are Qualideco accredited as “FILM SUPPLIER FS-005”: we produce high quality heat transfer film, an innovative material made entirely in Italy with advanced rotogravure printing equipment.

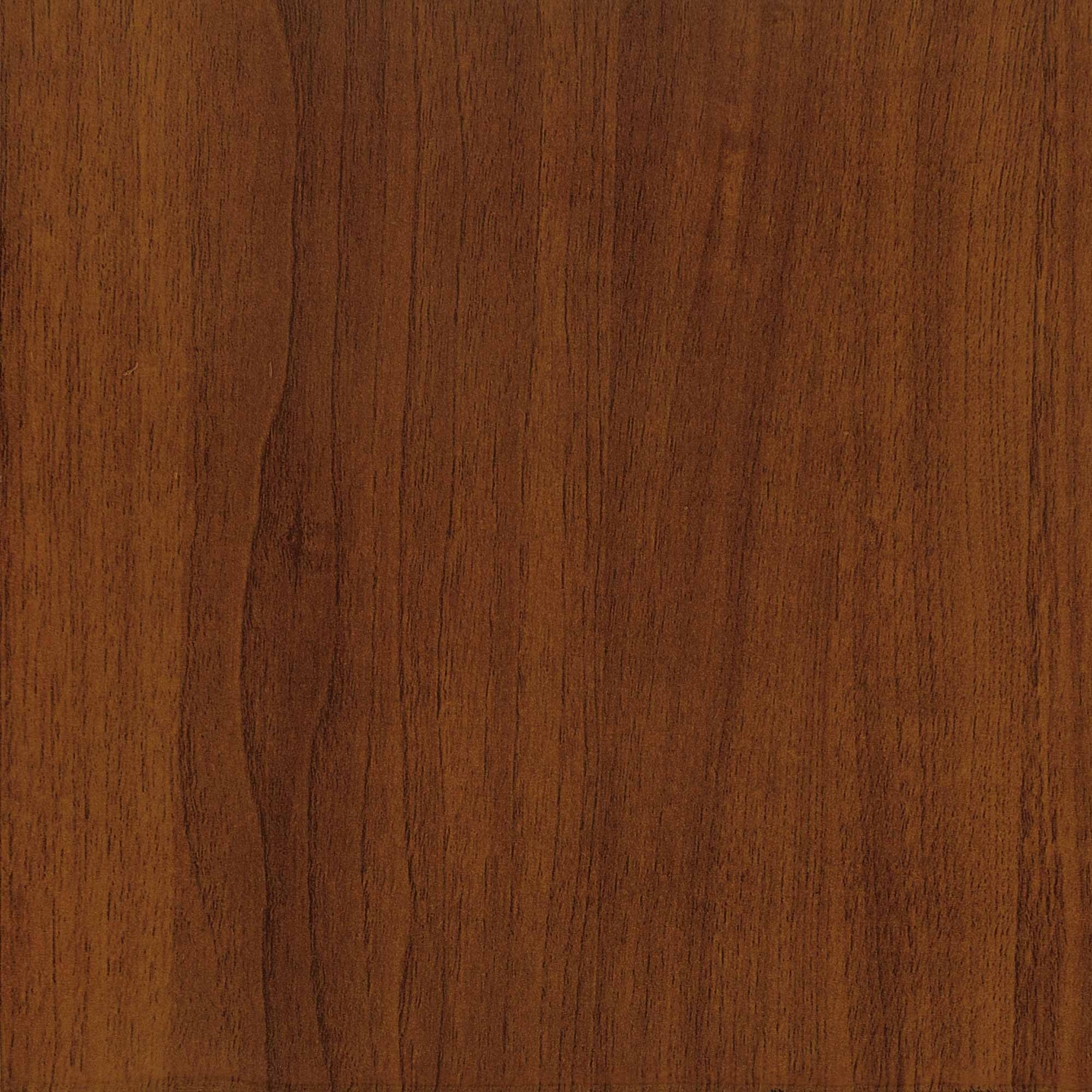

Our film is designed to accurately transfer the aesthetics of wood onto pre-painted metal surfaces through an efficient heat transfer process, with variable thicknesses ranging from 19 to 21 microns.

We guarantee excellent performance in terms of durability, with products bearing Qualideco class 1 and class 2 certification, synonymous with strength and reliability over time. We are actively committed to sustainability: our heat transfer films are the only films available on the market made from eco-friendly materials, using recyclable plastic films and water-based inks, which contribute to a significant reduction in their environmental footprint.

[01]

i.Transfer standard range

A QUALIDECO-certified supplier, I.DEK produces innovative and eco-friendly Heat Transfer Films in Italy, guaranteeing aesthetic quality, durability and sustainability.

[02]

i.Transfer SD

Special series with natural degradation pigments, suitable for exterior grade light colours.

SUBLIMATION PROCESS

Sublimation at I.DEK: protection and quality without compromise

The dye-sublimation process allows graphic images to be transferred using our i.transfers onto profiles, sheet metal and semi-finished metal products. This technology makes it possible to achieve decorative effects of high aesthetic quality, such as wood effect, patterns, stones and marble, by permanently fixing them on metal items.

To ensure the best result, any objects to be sublimated must be adequately prepared by thoroughly cleaning the surface and applying a powder coating treatment.

Once painted, the item is wrapped with the pre-printed transfer film, which adheres perfectly to the surface thanks to a vacuum suction process.

Next, the object is placed in an oven at temperatures of between 200° and 220°c for a predetermined time. during this stage, the design on the film sublimates from a solid to a gaseous state and is permanently absorbed into the paint layer.

Once the process is complete, the transfer film is removed, revealing the transferred design precisely and uniformly.

The end result is a high-quality finish that is highly resistant to atmospheric agents such as UV rays and temperature changes, as well as to wear and corrosion, while ensuring easy and long-lasting maintenance.